Introducing the structure of the winder

Release time:

2022-05-24

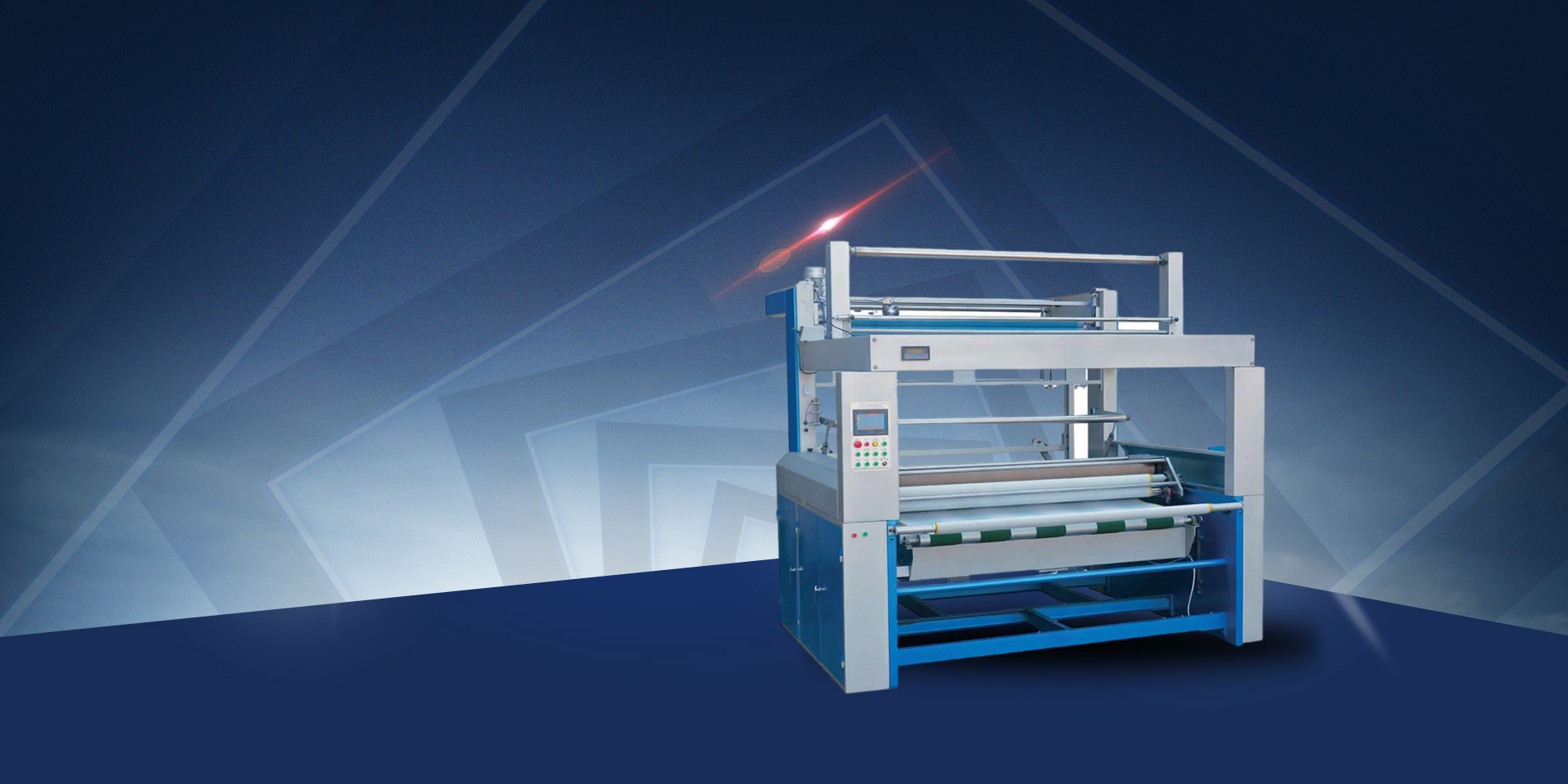

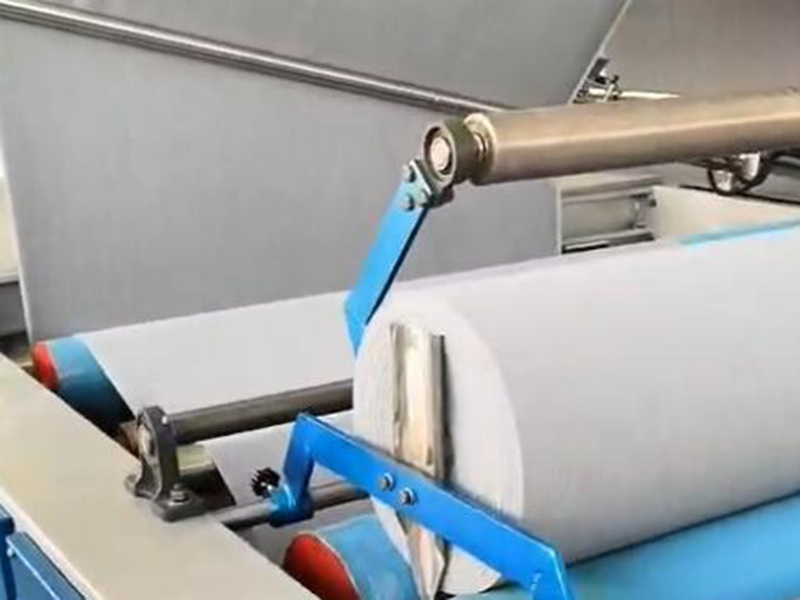

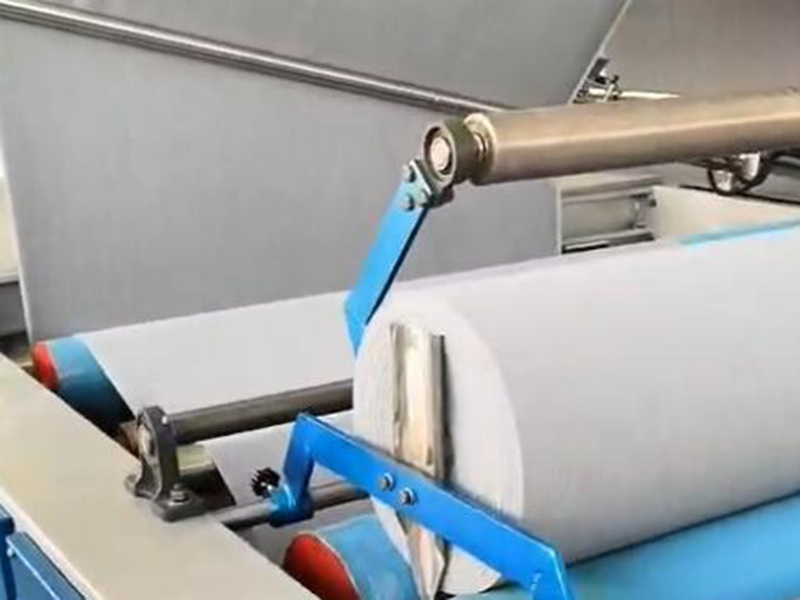

Nowadays, winders, including racks, are equipped with winders. The winder consists of clash rollers and air lift shafts arranged in parallel, as well as a pressure tissue for pressure organization. The air lift shafts are located close to or away from the clash rollers. Smaller diameter take-up rollers allow the diameter of existing take-up rollers to be changed, enabling rapid changes of take-up rollers.

Nowadays, winders, including racks, are equipped with winders. The winder consists of clash rollers and air lift shafts arranged in parallel, as well as a pressure tissue for pressure organization. The air lift shafts are located close to or away from the clash rollers. Smaller diameter take-up rollers allow the diameter of existing take-up rollers to be changed, enabling rapid changes of take-up rollers.

Provided with a temporary storage organization and a support roller, the feeding organization of the automatic steel strip winder can be placed in the temporary storage organization of the preparation roller, and the feeding organization of the support roller can be used even if the speed of the change-roll winder is very fast. In the temporary storage organization of the support rolls, the support rolls are also fed into the structure of the inverted roll winder.

The temporary storage of support rolls in this organization can be prepared in time without manual assistance, which can safely improve the production efficiency. Now it is attributed to the production of steel or existing skills mechanical slitting winder to solve the problem of unloading the existing skills of the organization of steel, it is difficult to achieve high-speed operation or reciprocating operation, and its high-speed standby unstable skills plan.

Now, the coiling machine is mainly used to progress in the process of high-speed linear reciprocating operation unloading steel organization stability. Now, the coiling machine is equipped with dust removal equipment, including coiling rollers organization, external powder and dust cover equipment, to improve the quality and utilization of coiling.

Tag:

Previous article

Mobile:

Tel:

Add: Dongshe Town, Tongzhou District, Nantong City, Jiangsu Province

Contact: 86-13901468376 Mr. Zhu

Tel: 86-513-82506284 / 86-513-82506333

Fax: 86-513-82506666

E-mail: sales@ntzhongyi.com

Website: http://www.ntzhongyi.com

HUATAO GROUP

Online Message

Please fill in the form below, our staff will contact you within 24 hours and solve your problem as soon as possible.

Copyright©2024 Nantong Tongzhou Zhongyi Textile Machinery Co., Ltd.