Talk specifically about the maintenance of the fabric inspection machine

Release time:

2022-05-11

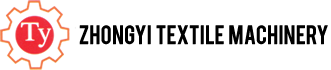

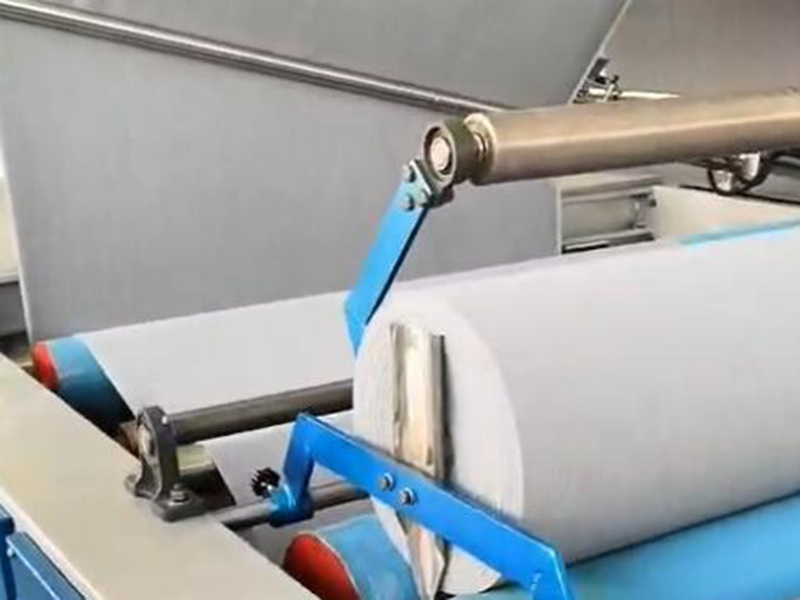

In the textile industry, fabric inspection machine is a household name for textile machinery, which is essential for the textile and garment industry. Fabric inspection machines are primarily used to detect flaws and different colors in fabrics and fabrics. They actively pack and measure the length of the opposite packages. Equipped with electronic drawback detectors, the results are analyzed and printed uniformly by computer.

In the textile industry, fabric inspection machine is a household name for textile machinery, which is essential for the textile and garment industry. Fabric inspection machines are primarily used to detect flaws and different colors in fabrics and fabrics. They actively pack and measure the length of the opposite packages. Equipped with electronic drawback detectors, the results are analyzed and printed uniformly by computer.

Since fabric testing machines are so useful, how do we protect them on a daily basis? Fabric inspection machine? Check all parts for wear, replace parts, stop then stop. Remove and replace. Machines must be viewed and repaired before they can continue to operate. The basic common sense of maintenance is something that every operator should know, it is a matter of serious interest.

Good protection and maintenance of fabric inspection machines can greatly improve their working power! With the development of production technology, the demand for cloth inspection machine is growing, and the significance of active cloth inspection is manual cloth inspection, manual measurement of cloth length, manual winding to active spraying, active winding and active measurement of cloth length. However, the development of the loom is now active, improving the production capacity of the artificial rack, reducing labor intensity, greatly improving production power.

The combination of checking and rolling process, constituting an organic whole, in order to maintain the continuity of production. The combination of computer monitoring technology makes the production process highly active, and then improve the production control and product quality. In short, the future development of fully active testing looms will continue to focus on high quality and high speed, and further improve the degree of activation and continuity, enhance the active control of information, processing and handling.

Tag:

Previous article

Next article

Mobile:

Tel:

Add: Dongshe Town, Tongzhou District, Nantong City, Jiangsu Province

Contact: 86-13901468376 Mr. Zhu

Tel: 86-513-82506284 / 86-513-82506333

Fax: 86-513-82506666

E-mail: sales@ntzhongyi.com

Website: http://www.ntzhongyi.com

HUATAO GROUP

Online Message

Please fill in the form below, our staff will contact you within 24 hours and solve your problem as soon as possible.

Copyright©2024 Nantong Tongzhou Zhongyi Textile Machinery Co., Ltd.